Tuesday, December 29, 2009

Week Nine Update - Rainscreens

Saturday, December 26, 2009

Start of Week Nine

As you can see from the photo, my daughter Ashley decided to get into the house-building business and made me a gingerbread house for Christmas. It's very cute and almost to scale - even simulated the important features such as the beams and windows. I wonder if the contractor will let me make a few late changes - cedar siding to gingerbread and the copper panels to Twizzlers? Probably not.

Today was our electrical walk-through. It was necessarily long (2 1/2 hours) and methodical. I've been anxious about this as I haven't had enough time with Carrie to review the many light fixtures that I've culled through. We also don't have prices from the distributer who will likely be supplying a lot of them. After I revise the fixture list this weekend, I'll be submitting that for the supplier's review.

Our house is not large, but the open/taller spaces provide an opportunity (read: challenge) to play off the architectural character. The upstairs walk-through took well over an hour but it is the hardest space to light since the ceilings are tall and have sloped ceilings and exposed beams. The challenge there is to gently light the ceiling, create a few hot spots on the floor, and wash light across the walls where art is likely to be placed. Doing this without creating a distracting clutter takes some consideration.

I also hesitate inserting any recessed fixtures into the insulated joist space. This would create another thermal break in the insulation and potentially create a condensation issue at the point where the hot fixture meets the cold from the outside. The solution seems to be track lighting dropped from the beams and smaller lights that can be flexed after installation.

The most unusual light fixture we have selected is over the dining room table. Instead of the usual pendant, we have chosen an 8' flexible track with 5 suspended lights. It is by design flexible and must be composed in the field. We'll also use a couple of these lights as pendants over the counter between the dining room and the kitchen.

One thing that has always puzzled me is how a three-way switch gets its name. I probably need to have one of our electrical engineers at work explain. A three-way switch has two switches that each connect to the same light fixture(s). A house will usually have a few of these - most often found in rooms that have a door to the outside. In locating lights and switches during rough framing, you have to figure out how each room will be used and where the furniture will be.

Now that the lighting and electrical is mostly behind us, the electrical sub can now begin wiring rough-in. Next up for me will be to design the stair and various railings. Carrie and I will also need to start selecting bathroom tile, kitchen backsplash, granite countertops, and the stone that will face the fireplace. That will keep us busy for a while.

Wednesday, December 23, 2009

Mechanical Installation

The basement was tested for Radon and as expected, it showed a high level - enough to warrant a mitigation system. We knew this after a letter showed up 6 months after we moved in - from a company who had performed a Radon test for the previous owners. The letter stated that high levels had been found and wanted to know if we wanted them to do the work that the previous owners had elected not to do. This should have been revealed to us at the time of purchase. Maybe I'll send their real estate agent the bill.

Radon is a radioactive gas that comes from the ground and is touted to be the second-leading cause of lung cancer. It can be pulled out of the ground through cracks and joints in concrete walls - essentially sucked out of the earth by the negative pressure that exists in most houses. You can find some useful information on the EPA website: http://www.epa.gov/radon/pubs/consguid.html#overview

There are simple methods to remove it from crawl spaces, slabs, and basements. The ususal one is "soil suction" - like the one being installed in our basement. As I understand it, a hole is drilled through the slab into the ground. You stick a sealed PVC pipe over the hole and try to pull air from the ground with a fan. This air is vented directly to the outside. Because our basement does not have a porous stone base under the slab -but was built directly on compacted earth, it means we need three holes instead of one. This system should become the conduit for the gas to escape. Hope it works.

At lunch on Tuesday, I walked around with Michael and Todd to determine where blocking and other framing will be needed prior to the electrical rough-in for items to be mounted on the wall like towel racks and toilet paper dispensers. The blocking will provide a screw-able surface and stiffen the wall.

We earlier had discussed a stategy for the mechanical duct around the top of the second floor ceiling - but elected to hold off a final decision until we could be in the space. I'm glad we deferred that as there are a couple tweaks that will make those taller spaces work better. Normally, I would have wanted to minimize the soffit height below the ductwork. However in this case, dropping it in the bedroom to line up with the window bay makes the most sense. It will also provide me a nice place to pocket the shading treatment and LED lights for the window bay. I should also be able to now get the glass panels above the closets between the bedroom and the den - making the exposed beams on the second floor more visible.

A rainstorm is expected on Christmas day. Maybe that will melt some of this snow and let them start working on the siding.

Saturday, December 19, 2009

Start of Week Eight

This morning was to be our electrical walk-through but there was no way that was going to happen with so many roads impassible. I was able to trudge the half-mile from our rental house to the construction site. It was a quiet walk right down the middle of the road - following in the wheel tracks of the few nuts who couldn't stay home. There were many people out socializing and shoveling snow - trying to free their cars and clear sidewalks while the snow was wet.

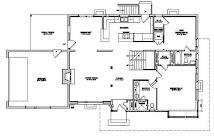

I spent almost 2 hours at the house trying to visualize some of the spaces and thinking through some of the details that are unresolved. These details include the rail design, HVAC framing, and lighting. It was great to just sit in the various framed spaces and visualize how it will be when closed up. It is now easier to decide where to throw light, put switches, and place furniture. I also noticed a few things that I'd like to tweak - one regarding the refrigerator depth, a change in strategy about lighting the living room, and another that has to do with the rail at the top of the stair. It's a good time to be noticing these things.

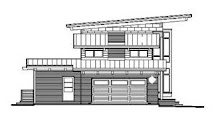

Overall, I am very happy with how the interior space works. It will be a wide open house that is filled with light during the day. The architecture certainly has a point-of-view, but when the materials on the outside are applied (and the white Tyvek is covered by the cedar), the house should pull back into the landscape more. This will continue over time when materials like the copper panels get their brown patina.

This week's homework will be mostly about getting ready for the rescheduled electrical walk-through. With this extra week and the chance to spend some "quality time" in the house, I can now coordinate the lighting cut-sheets with the plan. Carrie and I will also have more time to get on the same page.

Thursday, December 17, 2009

Tuesday, December 15, 2009

Week Seven Update

Being up on the second level will help me visualize how the lighting might work - particularly in those taller spaces with the exposed beams at the roof-line. Saturday will be our walk-through with the electrical contractor to review the electrical plan. It always amazes me how many things you need to think about to turn on the lights.

It is my desire to keep the lighting out of the ceiling cavity to maximize the effectiveness of the insulation. To do this, we'll be using pendants mounted to the ceiling surface and track suspended from the beams. The track will have lights that can be directed to throw light on the tall wall surfaces or bounce softer light off of the ceiling.

There are many decisions to be made at this point. This weekend, we finalized all of our pluming except for a pedistal sink and a vanity bowl. Today, I looked at 3 samples of finishes on the cedar siding. Up close, there was a noticable difference but from the street two of them seemed very similar. The same thing happened with the finish samples on the glue lam. I decided to use the redder, slightly darker stain on the siding so there will be less contrast with the dark windows frames. The red tint should provide some color too.

With the windows in place and all exterior surfaces insulated and covered with Tyvek, the cedar siding can now go up. That layer will really add some texture to the house. The contractor will start back-priming the cedar boards before they go up. This prime coat will coat the siding in all those areas that aren't visible and protect it from moisture that may get trapped inside the wall.

One other decision was to select the metal roof and metal fascia color - a medium bronze. This was a hard call for me. The roof over the living room and garage are minimally visible from the south so I elected to use a metal pan. Ideally, the material would be copper to match the panels directly under the overhangs. However, the copper will turn to brown within a year so all that expense would be lost on a large area of roof that is minimally visible. The medium bronze will hopefully match the copper once it ages.

At lunch today, I visited a company called Tektonics Design Group which is a creative studio and fabrication shop. They do every kind of design from metal connections to houses. Baskervill has been working with them on some specialty items that are really cool. My thinking is that they will be able to develop my thoughts on the stair and guardrail and then fabricate the items as well.

They will also take a look at bookshelves in the living room and a horizontal cover over the entry door. The bookshelves will be an important feature on this very tall (14') wall. My initial thought is to have them as a 9' "broken" grid of 18" square shelves. Perhaps Tektonics will take my concept to a more interesting solution.

Another detail that I'm getting them to take a look at is a horizontal "blade" of copper that could go above the front door. Because the roof overhang is so high above the entry porch, this item may be useful during a rainstorm from the south. Aesthetically, it will provide a protruding a horizontal line that is counter to the vertical windows that are around it.

I'll post some pictures on Wednesday after a visit at lunch tomorrow. I'm giving a quick tour to a couple co-workers who helped me at various points along the way.

Friday, December 11, 2009

Week 7

I asked the contractor to give me more time to design the stair and rails. These are very visible elements in the design and what I had started earlier just didn't make me happy. With Virginia's 4" rule for railing openings, the vertical pickets were just too opaque and at the balcony further accentuated the vertical character of the living room. They also hinted of a traditional design that was found nowhere else in the house. Instead, I am working on a design that is held up with thin darkly-painted thin metal posts and horizontal rods spaced at 4" centers. Wood will cap the rail.

I'm very happy with the way the glass bay on the front corner breaks up this otherwise flat facade. It appears delicate in contrast to the opaque walls around it - almost floating. This bay is very visible as you come up the steep hill after going under the railroad bridge.

Tuesday, December 8, 2009

Week Six Update

That detail now creates a decision for me. Do we replace the block with brick which will then be painted with the rest of the wall, or do we put a trim board over it. The latter is cheaper and might look just fine.

It is getting much easier to understand the volume which will be the living room. The front (tall) window is now framed in. To me, this is the most important, but undesigned room in the house. This room is most important because this is where all the special details and materials are seen - wood beams, unique windows, fireplace, balcony railings, and kitchen.

The more I see this room, the more important that the fireplace wall becomes. My original and current thought is to put a grid of bookshelves on either side of the fireplace - up to a 9' or 10' height. With the height of that wall, it will be important to use these as a design feature to humanize the 14' height. They should match either the height of the adjacent window or the ceiling line under the balcony. Pulling from one of these lines will help unify the space. The budget may delay this for the time-being.

It would be very dramatic to put the chimney stone on the inside face of the fireplace wall - all the way up to the ceiling. The wood ceiling beams will then frame either side.

I'm starting to realize just how many decisions are still to be made - and some design tweaks that I'm finding now that I see the space. Architects have an enhanced ability to understand theoretical space, but there's nothing quite like being in the actual built space to really see how space is connected and how the details intersect.

Saturday, December 5, 2009

Week 6

Tuesday, December 1, 2009

Roof Framing Goes Up Today

They expect to finish the roof framing of this section and have it dried-in by the end of the week. Great progress considering we've had 9.6 inches of rain since they started in early November.