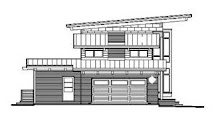

With a few days of sunshine, work on brick staining and metal roofing progresses. After these two items are complete there are just a few things left on the building exterior: the bluestone steps, painting the PVC trim, finishing the wood, then finally – applying the copper panels.

With a few days of sunshine, work on brick staining and metal roofing progresses. After these two items are complete there are just a few things left on the building exterior: the bluestone steps, painting the PVC trim, finishing the wood, then finally – applying the copper panels.The roofs over the living room and garage slope toward the south and are visible from the street. This is why we chose metal there instead of the white roof that is on the main roof and area over the back. The brown metal roof will approximate the color of copper patina seen on old pennies – and soon to be visible trim on our house. The white roof has a high reflectance and will reduce the cooling load in the summer.

This white roof is a TPO (thermoplastic polyolefin) material. It is now a standard roof on most commercial buildings with near-flat roofs, particularly popular in the south where cooling is the primary HVAC load. I have been told that the temperature of a TPO roof surface will be 20 degrees less than a black EPDM rubber roof. Environmentalists encourage use of this type of roofing as it reduces the heat-island effect found in cities.

The use of brick stain is a switch from our original plan to paint the brick. Baskervill used this product on an office building addition for WM Jordan here in town with impressive results. There, existing buff-colored brick was stained to match the red that was used on the addition. You cannot tell the difference.

My goal for the stain is to let some of the character of the old brick wall come through while neutralizing the exposed places where we patched and added brick. The old brick wall had a tan-colored mortar and a high percentage of flashed brick (the dark ones exposed to the flame when in the kiln.) A painted brick wall would need re-painting every 5 years or so. A stain should require much less maintenance.

I hope the stain works.

Looks like all your snow disappeared in 5 days? Wow! That helps the construction process!

ReplyDeleteGreat job, Mark!