5506 Riverside Drive Richmond, VA

Once again, there were 6 or 7 vehicles in front of our house this morning as I drove by. That is a good thing to see - and means progress is happening. I usually go by in the evening to check out what was done during the day. Some times it is obvious and other times you have to look for the small things. Today was more of a day for obvious things.

Once again, there were 6 or 7 vehicles in front of our house this morning as I drove by. That is a good thing to see - and means progress is happening. I usually go by in the evening to check out what was done during the day. Some times it is obvious and other times you have to look for the small things. Today was more of a day for obvious things.

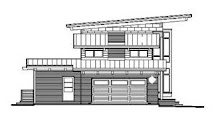

Gutters went up today and they look sharp. They match the metal roof color - both are painted with a Kynar paint which is very long-lasting. The color was chosen to approximate the copper after a couple years of patina. We'll see how good I guessed.

Gutters went up today and they look sharp. They match the metal roof color - both are painted with a Kynar paint which is very long-lasting. The color was chosen to approximate the copper after a couple years of patina. We'll see how good I guessed.The woodwork on the downstairs "window bench" was done today. It has wood flooring as a top surface with a rounded nosing similar to what is used at places like the balcony.

With all the trim in-place, the interior is nearly ready for paint. For several days, there has been a person going around filling the joints and nail holes with wood putty. Most of this seems complete and sanded.

We selected an off-white color for most walls and a semi-gloss white for the trim. This will keep things bright and will highlight the trim around the door and window openings. I'm curious to see how this all looks. We'll probably add some richer colors to accent walls and the upstairs bedroom.

I had to spend a few evenings at work this past week and cut grass and do yardwork at two houses today. Finally, I can take some time to post a note. The work at the house the past few days was about finishing things that began last week:

I had to spend a few evenings at work this past week and cut grass and do yardwork at two houses today. Finally, I can take some time to post a note. The work at the house the past few days was about finishing things that began last week:It's starting to look livable. The big interior items remaining are lights, bookshelves, countertops, plumbing fixtures, appliances, paint, and floors sanding/finishing. It's getting to be a shorter list but this work is time-consuming and many can't be done until others are out of the way.

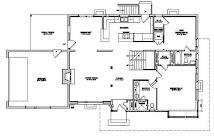

One of the visitors is said to be a lady who grew up in the house and still lives in the neighborhood. Her father built the house in 1955. Carrie spoke to her once when the lady drove by the house and told her about her time there. I hope she is not too upset about the dramatic changes we made. Believe it or not, a great deal of the original house is still underneath and we kept the much of the basic layout. We just added to it.

One of the visitors is said to be a lady who grew up in the house and still lives in the neighborhood. Her father built the house in 1955. Carrie spoke to her once when the lady drove by the house and told her about her time there. I hope she is not too upset about the dramatic changes we made. Believe it or not, a great deal of the original house is still underneath and we kept the much of the basic layout. We just added to it.

This latter part of this week saw a couple more interior features installed.

This latter part of this week saw a couple more interior features installed. The smallest dimension of the stair was just a bit larger than the 36" front door. We had known this since the design was worked out with the fabricator. To minimize the amount of work required at the site, the contractor figured out another way to get them in the house - removal of a bedroom window sash on the first floor. It took 3 or 4 guys to manhandle it from the front yard and down the hall. Too bad I don't have a picture.

The smallest dimension of the stair was just a bit larger than the 36" front door. We had known this since the design was worked out with the fabricator. To minimize the amount of work required at the site, the contractor figured out another way to get them in the house - removal of a bedroom window sash on the first floor. It took 3 or 4 guys to manhandle it from the front yard and down the hall. Too bad I don't have a picture.