It has been amazing to witness the evolution of sustainable design over the last ten years. It was ten years ago this summer when my team at Baskervill first proposed a few sustainable concepts into a project. While gathering information about our new client - the United Methodist Church of VA, I found a strong policy statement on their national website about their stewardship of the environment. With the help of Rebecca Aarons (our only expert in an office of 100+ design professionals), we proposed some basic sustainable concepts to our client.

Doing anything “green” at that time was challenging.

Very few consultants understood sustainable design concepts, green materials were not readily available, and the officials who reviewed building projects were less than cooperative. To become an expert in the subject, Rebecca spent a lot of personal time researching sustainable methods and materials. To our delight, many of her ideas were accepted by the client and became part of the project.

Ten years later, sustainable design is now seen at Baskervill as one of our standard services. There are evolving guidelines and certifications which are embraced by the people who opposed our goals ten years ago. Today, it is hard to find a material that doesn’t tout its green qualities. As ubiquitous as it seems within the industry, there is a very long way to go.

Improving the efficiency of our vehicles is an important and visible goal - but did you know that the energy consumption of buildings in the US dwarfs that of all our cars and trucks? One recent report stated that the energy saved from simply re-glazing all single-pane windows in America with double-panes would equal that produced by 300 power plants. It is the responsibility of my profession to change the way we design buildings – to make them smarter, use less energy, and be made of materials that retain some value at the end of their life.

My personal philosophy regarding sustainable design comes from what I learned as a Boy Scout. Camping, hiking, and canoeing got me out of the city and into nature. I gained a deep respect of the environment and grew to understand that we are not only part of nature but also its care-takers. Just as scouts leave a campsite "better than we found it", we should strive to do the same with our impact on the environment.

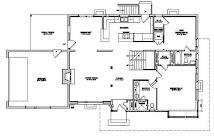

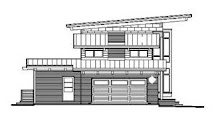

The renovation of our Riverside house employs several sustainable strategies that will be explained in future posts. Carrie and I decided not to pursue LEED certification because doing so for a house is very expensive and heavy on administration. LEED stands for “Leadership in Energy and Environmental Design” and is a broad rating system that is now widely used for many commercial and public projects. Its priorities include community resources, site development, water efficiency, air quality, energy, and materials.

Though not pursuing certification, I am using the new LEED for Homes checklist as a measuring stick and am trying to do enough items on the list to exceed their Silver rating threshold.

Another accepted guideline for new homes is Earthcraft. It looks primarily at energy consumption and air quality. At this time, their point-system is geared to new homes – and not renovation like ours. Earthcraft guidelines are thoughtful and eventually may have a large impact nationwide due to its lower administrative costs.

These programs are all leading change in the construction industry. Inevitably, elements of these sustainable programs will be integrated into the building code. To Carrie and me, what is most important is not certification in any particular program, but doing those things which will have the greates effect (and) also make economic sense.

We also began picking out furniture with the help of Carol Hochheiser-Ross, one of Mark’s partners at Baskervill. We will have a round dining room table with upholstered Parson chairs. We also selected 4 chairs for the living room, opting to go with chairs instead of a sofa in that room. Now, we need to make the fabric selections. Before we do, we need to think about wall colors and the mood we want to set in each room. Decisions, decisions…..

We also began picking out furniture with the help of Carol Hochheiser-Ross, one of Mark’s partners at Baskervill. We will have a round dining room table with upholstered Parson chairs. We also selected 4 chairs for the living room, opting to go with chairs instead of a sofa in that room. Now, we need to make the fabric selections. Before we do, we need to think about wall colors and the mood we want to set in each room. Decisions, decisions…..