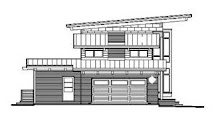

Whether we are here to watch or not, work on the house moves forward. Lots of little things are happening this week at the house. On the exterior:

- Cedar trim is going up around the eaves.

- The wall area under the back eave is now covered.

- Plywood (to be stained) is now covering some of the roof soffit between the beams.

- More [white] PVC trim is edging the windows, ready to be painted.

- The stone chimney is finished.

On the inside:

- The upstairs HVAC unit is now in the closet and most (if not all) of the ductwork is complete.

- The box-framing around the ductwork is done.

- Much of the wiring has been pulled. The rest must wait till some of the low-voltage fixtures are on site.

- The radon pipes are grouted into the ground

- The tankless water heater is hooked up.

When doing a custom house from scratch or an extensive remodel such as this project, an Owner should know that there are many, many decisions to make.

One of our most important interior finishes will be the wood that is scattered about. It is a unifying material, and is found on most floor surfaces. The other places wood will be used are the kitchen cabinets, doors, and tops of the rails. Each of these will be finished by different people and in different places.

If the object is to closely match these finishes, you need to start with the finish that is least flexible. In our case it is the doors. They will have a standard "honey" finish over maple (the right-most sample seen in the adjacent image). The cabinet maker and rail fabricator can tweak their finishes more easily and will do their best to match the door finish.

Because the floor touches the doors and the cabinets, it is probably best not to attempt to match the finish - because you never will. The floor is oak and all other woods are maple. Oak has a heavy grain and maple is more subtle. Our choice will probably be to finish the oak floor darker than the other items - perhaps with a tint of red as well to recall the cedar finishes outside.

Next week, I'll probably bore you with some of the "green" aspects of the house. This can get technical but is important if you want to save money and minimize your carbon footprint.

Mark, your home looks incredible. I can hardly wait to see it when it is finished. Keep up the beautiful work.

ReplyDelete